NiTi Shape Memory Alloys (SMAs)

Reginald F. Hamilton, Prof. Huseyin Sehitoglu

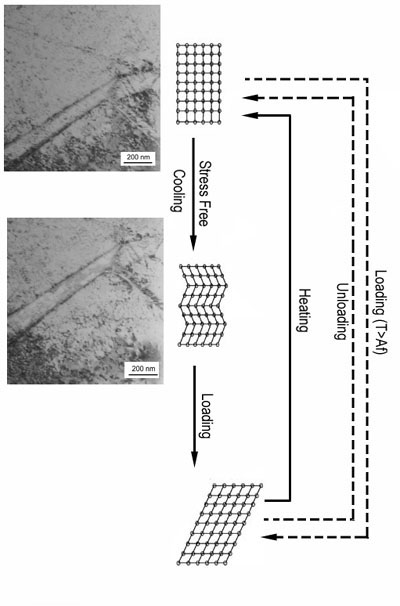

Here the Shape Memory Effect is characterized by the deformation of a matrix. The accompanying micrographs of an NiTi single crystal specimen show the behavior captured in the laboratory.

Several experiments are performed to study the material behavior of NiTi shape memory alloys (SMAs).

When acted on by an external driving force (e.g. temperature, stress, strain, or magnetic field), SMAs undergo a solid state phase transformation, referred to as a martensitic transformation. If the driving force is temperature, SMAs transform from a high temperature parent phase (austentite) to a low temperature product phase (martensite).

Thus, an SMA material can be cooled so that the material achieves a martensitic phase. The material can then be subjected to an applied load, and the material will return back to its original shape and crystallographic orientation when heated. Because of the nature of the microscopic transformation, the material “remembers” its original shape when heated.

Uniaxial tension/compression and fatigue, DSC, resistivity, and magnetic experiments are performed to evaluate and characterize shape memory behavior.

Related Publications:

- Sehitoglu, H., D. Canadinc, R. Hamilton, X. Y. Zhang, K. Gall, I. Karaman, Y. Chumlyakov, and H. J. Maier, “Detwinning in NiTi Alloys,” Metallurgical and Materials Transactions, 34A, 2003.

- Y. I. Chumlyakov, E. Yu Panchenko, I.V. Kireeva, S. P. Efimenko, V. B. Aksenov, and H. Sehitoglu, “Dependence of Shape Memory Effect and Superelasticity on the Number of Variants of Disperesed Particles in Titanium-Nickel Single Crystals,” Doklady Physics, 47, 510, 2002.

- Gall, K., M. Dunn, Y. Liu, P. Labossiere, H. Sehitoglu, and Y. I. Chumlyakov, “Micro and Macro Deformation in Oriented NiTi Single Crystals,” Journal of Engineering Materials and Technology A, 124, 238, 2002.

- Sehitoglu, H., J. Jun, X. Zhang, I. Karaman, Y. Chumlyakov, H. J. Maier, and K. Gall, “Shape Memory and Pseudoelastic Behavior of 51.5% Ni-Ti Single Crystals in Solutionized and Overaged State,” Acta Materialia, 49, 3609-3620, 2001.

- Gall, K., K. Juntunen, H. J. Maier, H. Sehitoglu, and Y. I. Chumlyakov, “Instrumented Micro-Indentation of NiTi Shape Memory Alloys,” Acta Materialia, 49, 3205-3217, 2001.

- Sehitoglu, H., R. Anderson, I. Karaman, K. Gall, and Y. Chumlyakov, “Cyclic Deformation Behavior of Single Crystal NiTi,” Materials Science and Engineering, A314, 67-74, 2001.

- Gall, K., H. Sehitoglu, R. Anderson, I. Karaman, Y. Chumlyakov, and I. V. Kireeva, “On the Mechanical Behavior of Single Crystal NiTi Shape Memory Alloys and Related Polycrystalline Phenomenon,” Materials Science and Engineering, A317, 85-92, 2001.

- Sehitoglu, H., I. Karaman, R. Anderson, X. Zhang, K. Gall, H. J. Maier, and Y. Chumlyakov, “Compressive Response of NiTi Single Crystals,” Acta Materialia, 48, 3311-3326, 2000.

- Gall, K., T. J. Lim, D. McDowell, H. Sehitoglu, and Y. I. Chumlyakov, “The Role of Intergranular Constraint on the Stress Induced Martensitic Transformation in Textured Polycrystalline NiTi,” International Journal of Plasticity, 16, 1189-1214, 2000.