Linking Wear, Microstructure, and Mechanical Properties

Demircan Canadinc, Prof. Huseyin Sehitoglu

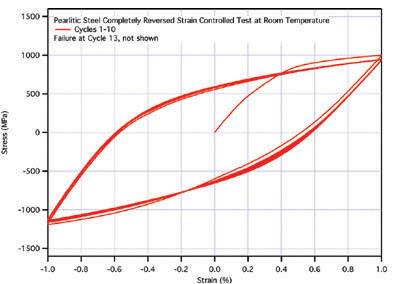

This project is supported by AAR / TTCI. Bainitic and pearlitic steels utilized in the railroads are investigated on a comparative basis. It is aimed to link wear, microstructure and mechanical properties to explain the reported difference between the performances of these materials on the track. Specimens cut from used (tested in a test track) or unused rails are subjected to mechanical testing (tensile, compressive, or cyclic) in order to establish the fundamental mechanical properties and the difference between the two materials. Transmission Electron Microscopy is utilized to reveal the microstructural changes and due to deformation of these materials at different deformation stages, as well as the difference between the two materials. X-Ray Diffraction microscopy is utilized to observe the relationship between the texture of the material and the state of deformation. This information is also used as an input to a visco-plastic self-consistent model simulating the plastic deformation during the wheel/rail interaction, taking the effect of texture into account.

This project is supported by AAR / TTCI. Bainitic and pearlitic steels utilized in the railroads are investigated on a comparative basis. It is aimed to link wear, microstructure and mechanical properties to explain the reported difference between the performances of these materials on the track. Specimens cut from used (tested in a test track) or unused rails are subjected to mechanical testing (tensile, compressive, or cyclic) in order to establish the fundamental mechanical properties and the difference between the two materials. Transmission Electron Microscopy is utilized to reveal the microstructural changes and due to deformation of these materials at different deformation stages, as well as the difference between the two materials. X-Ray Diffraction microscopy is utilized to observe the relationship between the texture of the material and the state of deformation. This information is also used as an input to a visco-plastic self-consistent model simulating the plastic deformation during the wheel/rail interaction, taking the effect of texture into account.